Additional services and precision machining

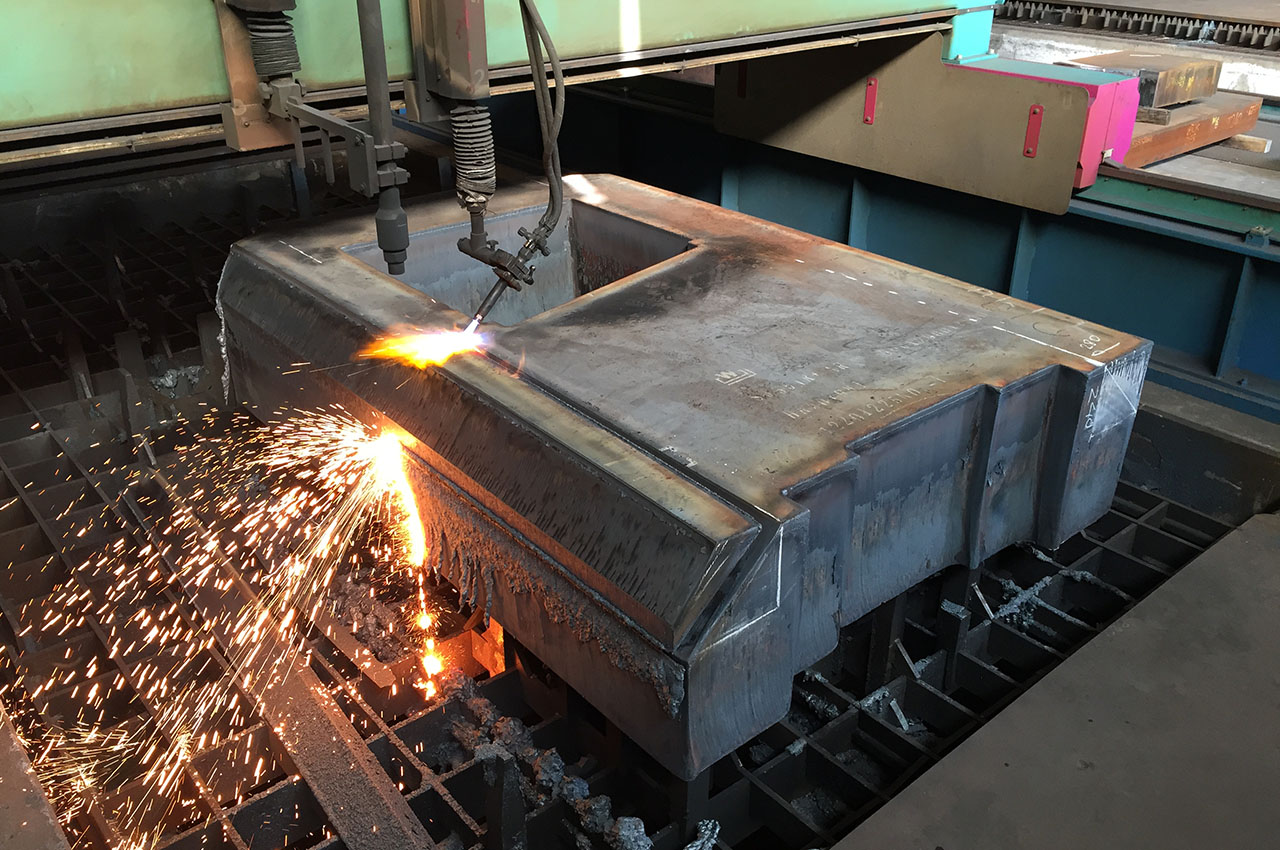

Ferrato Davide Sas selects the raw material from the best national and international metalworking mills for the production of sheet metal, re-rolled slabs and thick sheets produced by forged ingot.

The company acts as an intermediary between producers and final customers providing logistic and commercial services. Upon request we finish the customized product with fast, precise and professional services.

Deburring machine Costa mod.Md7

Ferrato Davide S.a.s. expands its range of machinery, introducing a deburring machine with an high technological innovation, to modernize its production process and add value to the product, according to the customer’s needs.

It’s equipped by brushes, which have the purpose to deburr in a heavy way and to clean all the internal and external cutting perimeter of the steel shapes, removing any sharp edges.

It’s composed by a work area of 1650 mm of width and it guarantees a professional finish up to 250 mm of thickness.

This new investment it’s an additional service in order to remain competitive in the market, to automate the production cycles as much as possible, and to improve not only the working conditions of the skilled workers but also the environmental conditions.

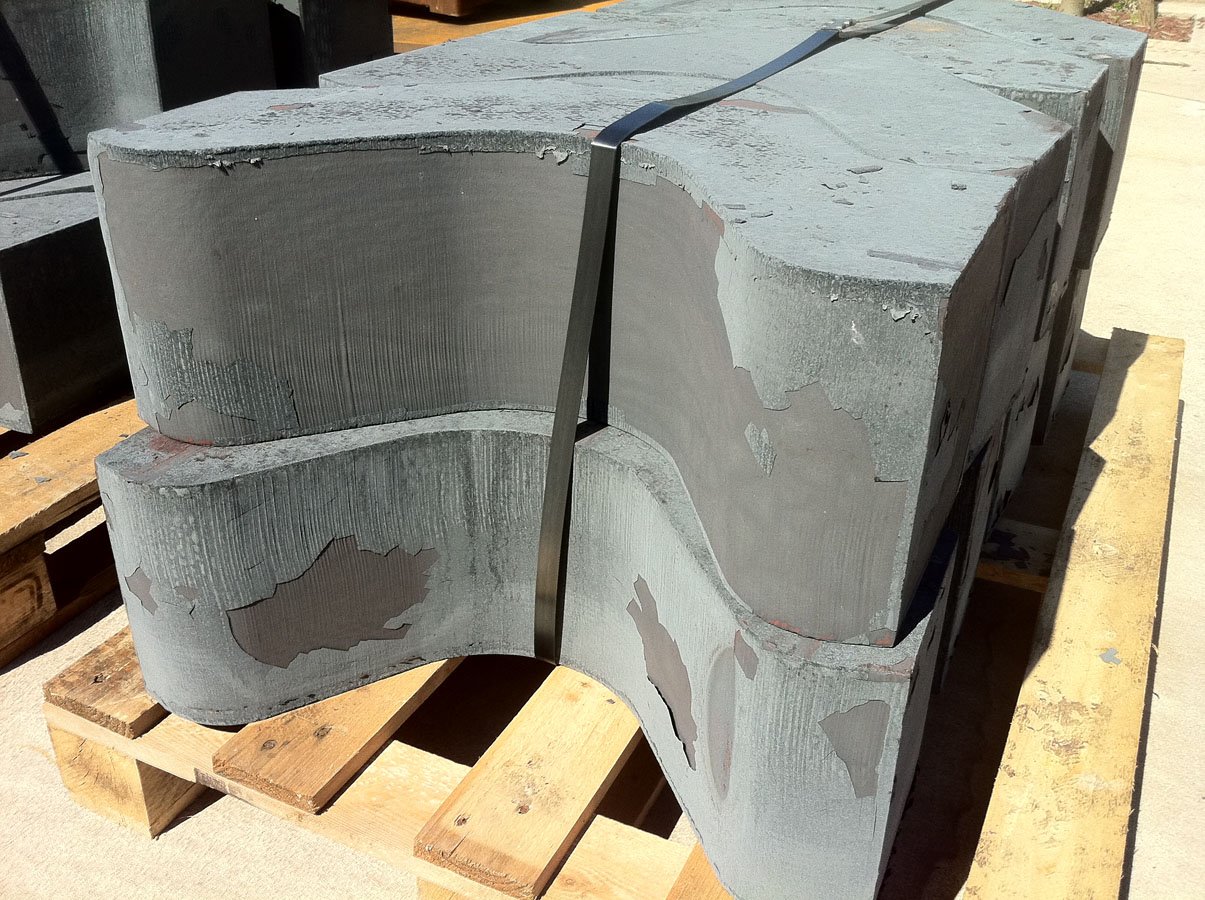

Tumbling

Machining of surface finishing. It is typically used for the mechanical removal of substrate residues, and occurs by rolling and colliding pieces in a barrel called a “buratto”.

Ultrasound

The ultrasonic method is performed by specialized technicians, and it is fundamental to examine the homogeneity and the correct conformation of thick sheets.

Sandblasting

Sheet sandblasting is a sheet metal cleaning process, intended for the removal of rust, paint and encrustations deriving from previous procedures, through a jet of sand and air that hits its surface.

Normalization

The normalization is a heat treatment which consists in heating the material at a temperature lower than the melting temperature, followed by a slow cooling in the oven which allows the steel to obtain a more homogeneous structure.

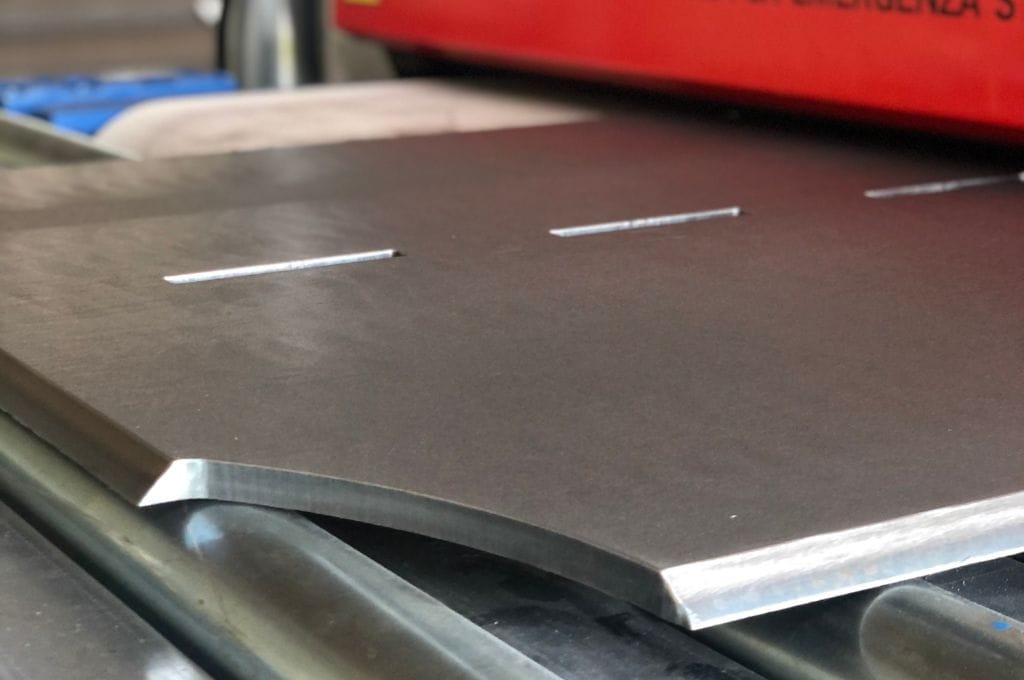

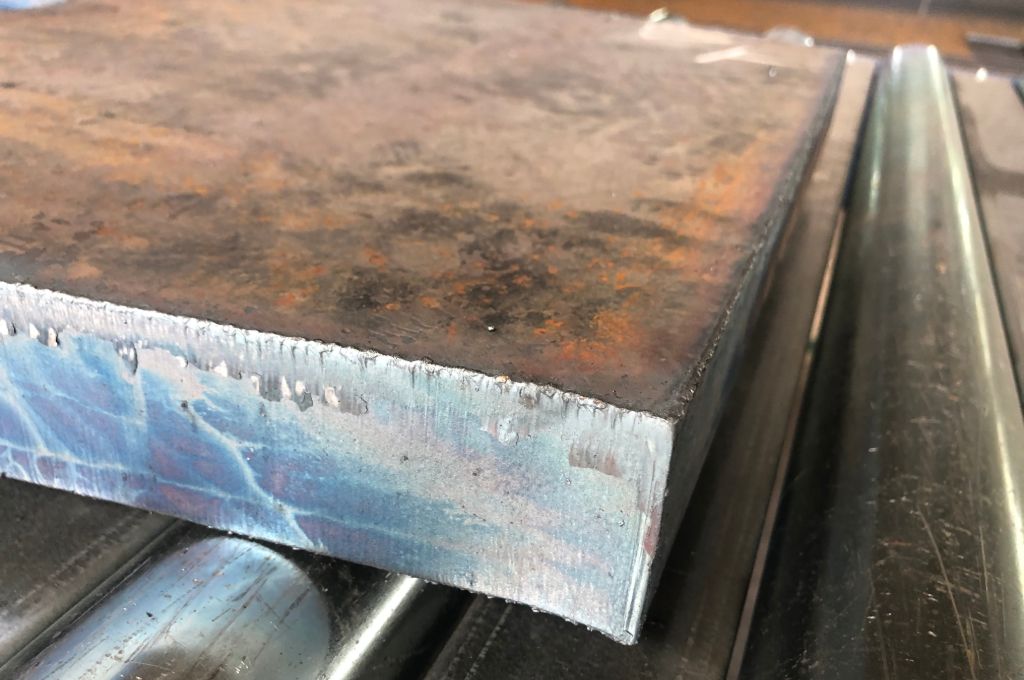

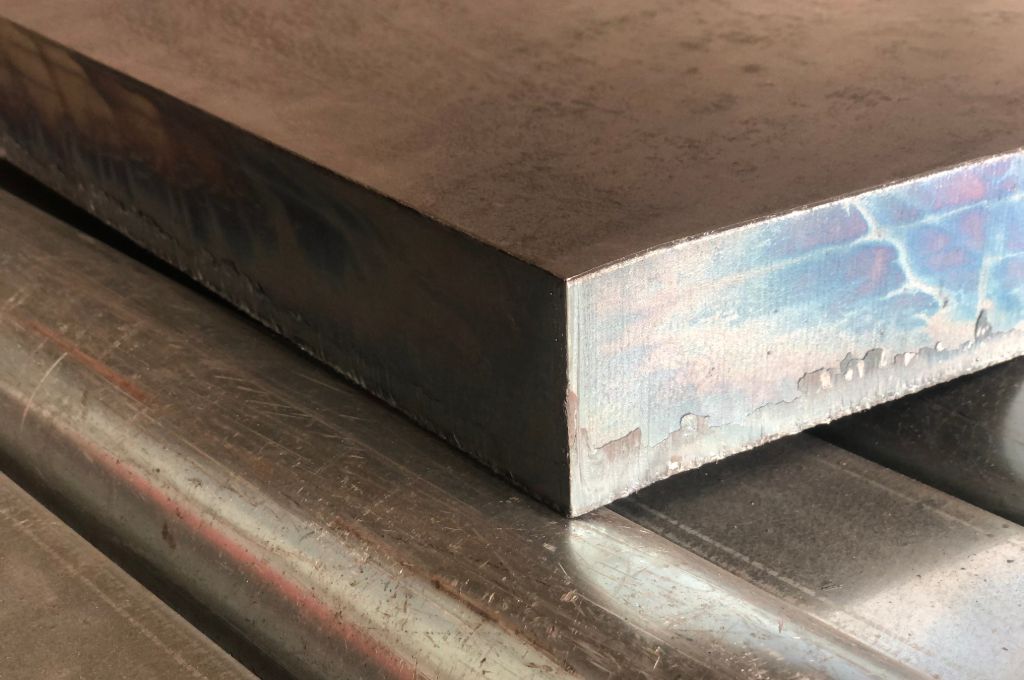

Deburring

It consists in the removal of “burrs”, that is, of excess material in the products obtained from mechanical or cutting processes, eliminating excess material along the contours of thick shapes.

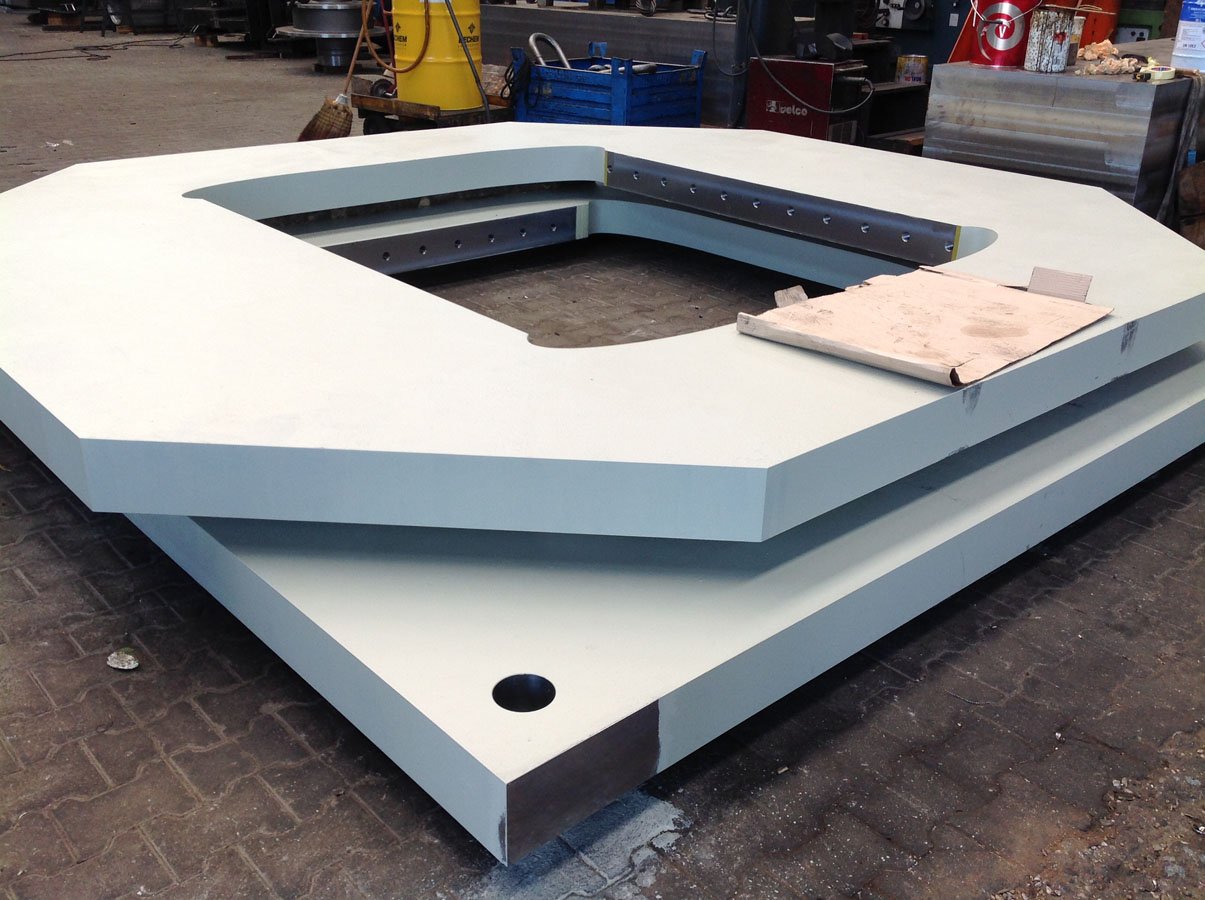

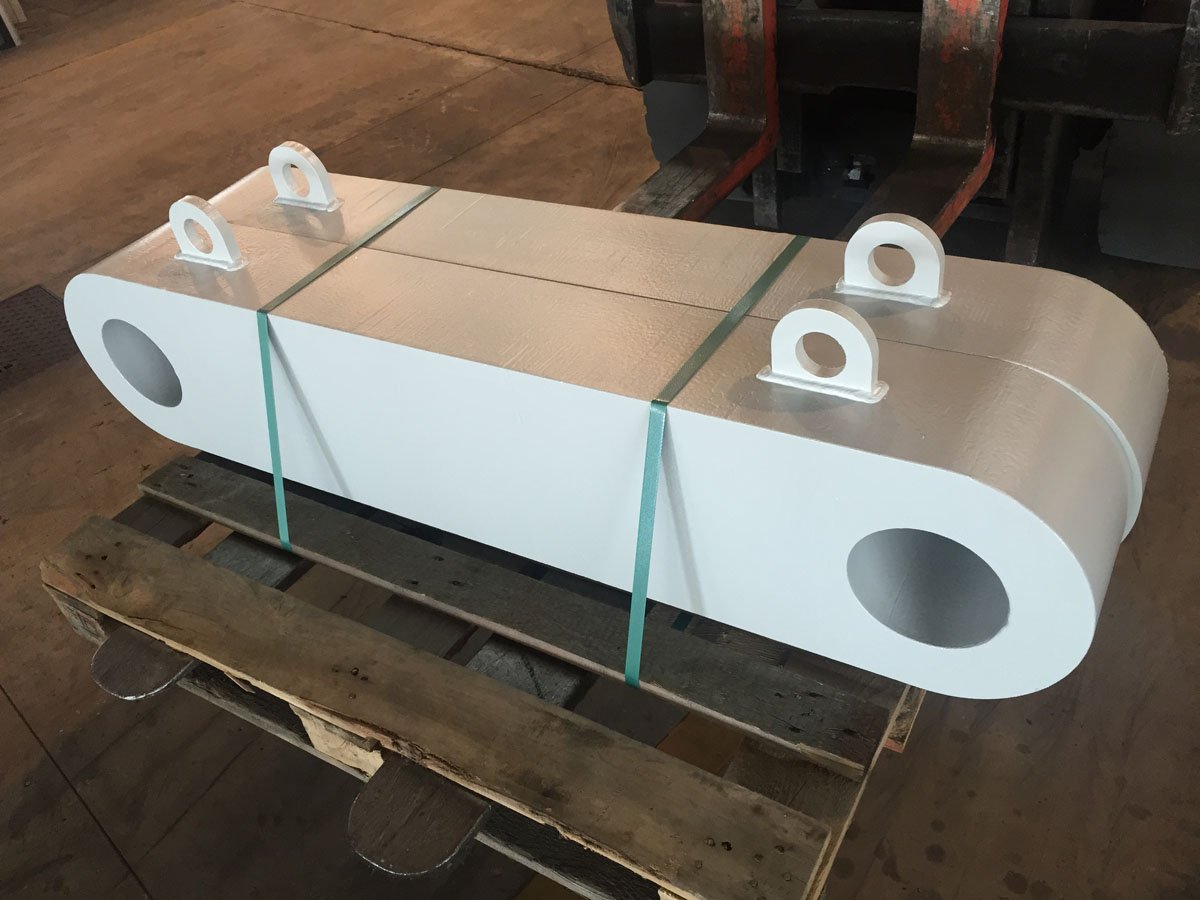

Priming

The sheet can undergo a priming treatment: a thin layer of antioxidant product based on zinc is laid which protects the sheet sanded by oxidation.

Straightening

This process allows thick metal sheets to optimize and improve flatness through the use of a press.